Being a mathematician, I am having difficulty getting my fluid-dynamics papers accepted for publication. So I have come to the realization that mathematics and physics papers are vastly different.

The methodology in a mathematics paper is at least as important as the result; there are cases where a shorter proof generates almost as much excitement as the original.

It appears that for physicists, the result is paramount and the methodology is mainly for vetting the results. To develop an elegant theory which provides results which are already known is of no interest; there must be some lack or deficiency in a known result for the physicist to read past the abstract. And that lack or deficiency must be stated up front; one of my papers was rejected because it didn't tell a story.

Mathematicians tend to read a paper from start to finish and are delighted by footnotes with unexpected connections to other fields. The Journal of Fluid Mechanics nearly forbids footnotes in their instructions for authors.

There are variations among physics journals as well. For journals with an engineering bent, stating that a coefficient of 0.450 is actually sqrt(2)/pi is probably best left out.

Voluntocracy

Governance by those who do the work.

Monday, May 11, 2020

Saturday, September 21, 2019

Real-time interactive mathematical marbling

Blake Jones has done some righteous coding, creating a GPU implementation of the Oseen flow in paint marbling algorithm which executes so fast that it renders the marbling from arbitrary stylus movements interactively in real time! The first video on his Turing clouds webpage shows the system in action.

Labels:

mathematical marbling,

Oseen flow,

paint marbling

Thursday, February 7, 2019

Mathematical Marbling How-To

http://people.csail.mit.edu/jaffer/Marbling/How-To

Pst-marble (and documentation) is a CTAN package for the LaTeX document system. If you have LaTeX and CTAN installed on your computing device, then you can create marblings locally. https://www.latex-project.org/get/ has the downloads and instructions for installing LaTeX and CTAN on GNU/Linux, MacOS, and Windows.

For those with a web-browser, it is easy to create marblings online. Papeeria.com provides an online LaTeX workbench with free and paid accounts. The marbling example files will render in less than one minute; so a free account is sufficient for exploring. If you create more complicated designs, you can upgrade to a paid Papeeria account or install LaTeX and CTAN on a (larger) computing device.

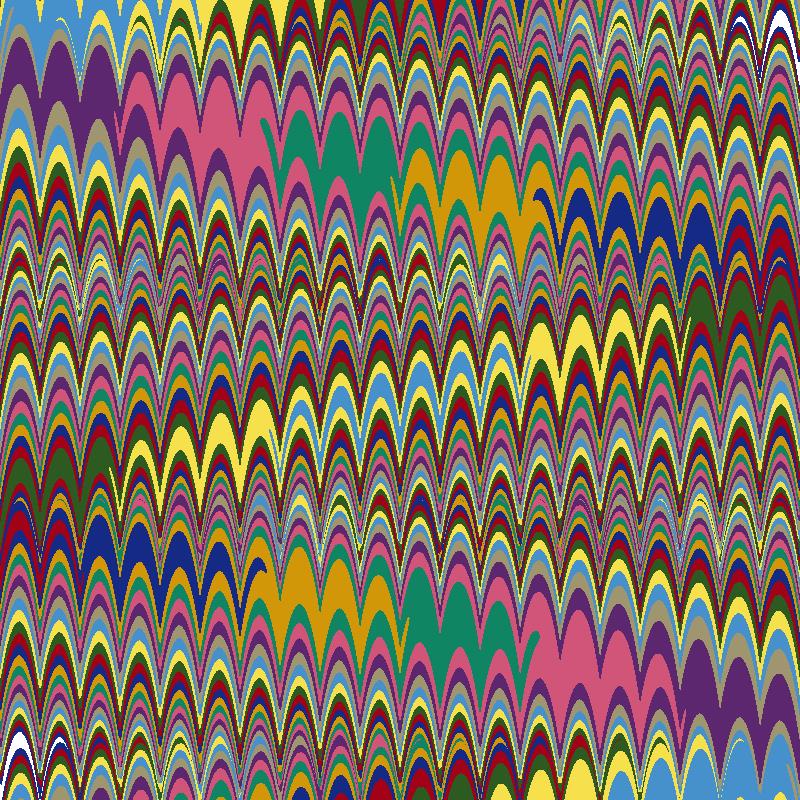

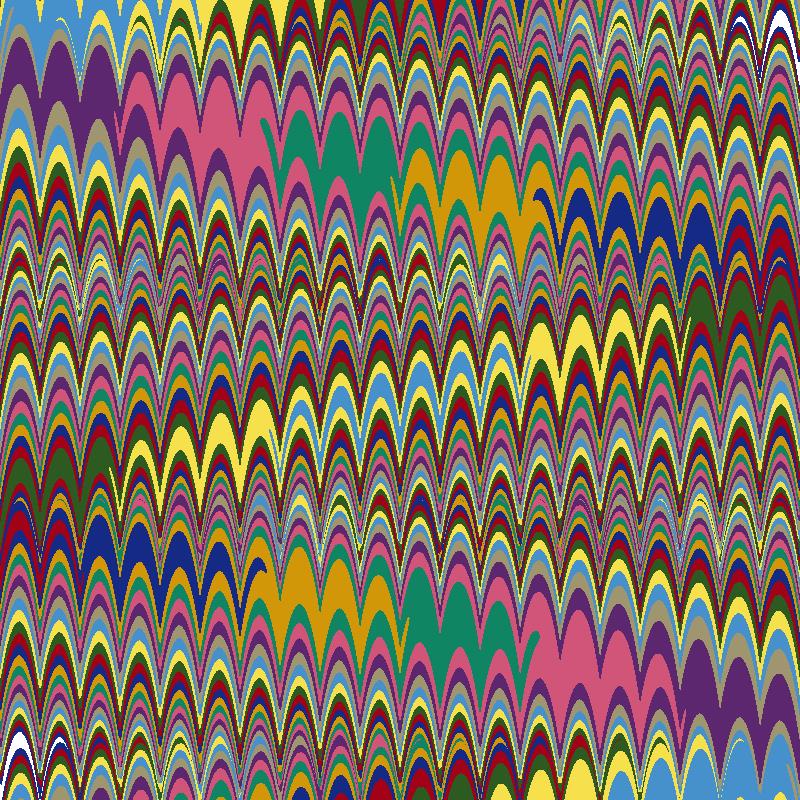

Low resolution rendering of Nonpareil.tex

Returning to the Nonpareil.tex code: After

the \psMarble line there are several sections bounded by

curly braces { and }.

The

The

Comment out four lines of the

0 0 48 [(c28847) [231 204 155] [0.635 0.008 0.094]] 25 concentric-rings Next, uncomment the first two

"

Raking left and right increases the number of color bands. The next step will rake downward with 25 tines. While we could specify their positions as 25 numbers between brackets, pst-marble offers a utility for generating evenly spaced tines:

The pst-marble reference card gives brief descriptions of all the

Copyright © 2019 Aubrey Jaffer

Paint marbling is a process of dropping colored paints onto a liquid bath and raking (combing) them to create intricate designs. Based on my mathematical theory of marbling, Jürgen Gilg, Manuel Luque, and I have created the pst-marble software to enable anyone with an internet browser to create their own digital marbled designs.

Pst-marble (and documentation) is a CTAN package for the LaTeX document system. If you have LaTeX and CTAN installed on your computing device, then you can create marblings locally. https://www.latex-project.org/get/ has the downloads and instructions for installing LaTeX and CTAN on GNU/Linux, MacOS, and Windows.

For those with a web-browser, it is easy to create marblings online. Papeeria.com provides an online LaTeX workbench with free and paid accounts. The marbling example files will render in less than one minute; so a free account is sufficient for exploring. If you create more complicated designs, you can upgrade to a paid Papeeria account or install LaTeX and CTAN on a (larger) computing device.

- Download pst-marble-v1.4.zip (15 kB) onto your computing device.

- Go to http://Papeeria.com and create a free account for yourself and a "project" with whatever name you like.

- From the top left pull-down select Upload Project, then Choose files and select pst-marble-v1.4.zip which you just downloaded. Then click Open.

- In the Project tab you should then see a list of filenames. The files with capitalized first letter and ending with .tex are the marbling example files.

- Click on Nonpareil.tex and you will see lines of text which are a small marbling program. Find the Papeeria Compile pull down and click on Nonpareil.tex. In less than 30 seconds a colorful design will appear in the PDF tab (you may need to install a PDF viewer on your device).

Low resolution rendering of Nonpareil.tex

colors= section accepts RGB colors in three formats.

- [0.906 0.8 0.608]

- Red, green, and blue color components between 0 and 1 in square brackets.

- [231 204 155]

- Red, green, and blue color components between 0 and 255 in square brackets.

- (e7cc9b)

- Red, green, and blue (RRGGBB) hexadecimal color components between 00 and fF in parentheses.

% is the comment character

in .tex files. Text to the right of % is

ignored to the end-of-line. Try commenting out some color

lines, then click on Papeeria's Compile button; you should

see fewer colors in the resulting marbling PDF.

The

actions= section in Nonpareil.tex

specifies the marbling design through a sequence of numbers

(arguments) and commands separated by whitespace. The system

is a bit unusual in that the command is to the right of its

arguments. The leftmost two arguments to most of the commands

are the x and y coordinates of the center of the

marbling action. 0 0 for the first two

arguments specifies the center of the design. The

visible x and y for a square image are from -500 to

+500; but the virtual tank is infinite in size.

Comment out four lines of the

actions= section so that

it looks like this; then Compile:

0 0 48 colors 25 concentric-rings % 90 [-150 450] 100 750 31 rake % -90 [-150 450] 100 750 31 rake % 180 [ 25 50 0 tines ] 30 200 31 rake % 0 230 shiftYou should now see concentric colored rings in the PDF viewer. These are produced by

concentric-rings command:

- x y Ri [rgb ...] n concentric-rings

- Places n rings in color sequence [rgb ...] centered at location x,y, each ring having thickness Ri.

colors argument refers to the color

sequence from the colors= section. It can be replaced

by a literal color sequence; for instance:

0 0 48 [(c28847) [231 204 155] [0.635 0.008 0.094]] 25 concentric-rings Next, uncomment the first two

rake lines so that

the actions= section looks like this;

then Compile:

0 0 48 colors 25 concentric-rings

90 [-150 450] 100 750 31 rake

-90 [-150 450] 100 750 31 rake

% 180 [ 25 50 0 tines ] 30 200 31 rake

% 0 230 shift

- θ [R ...] V S D rake

- Pulls tines of diameter D at θ degrees clockwise from the positive y-axis through the virtual tank at velocity V, moving fluid on the tine path a distance S. The tine paths are spaced [R ...] from the tank center at their nearest points.

90 [-150 450] 100 750 31 rake" rakes two tines from

left to right.

"

-90 [-150 450] 100 750 31 rake" rakes two tines from

right to left. The tine tracks are distinct from the previous two

because they are rotated 180 degrees. It is important to offset the

tines so that rakes in opposite direction do not cancel each other

out. You can see this cancellation by changing [-150

450] to [-300 300] in both lines.

Raking left and right increases the number of color bands. The next step will rake downward with 25 tines. While we could specify their positions as 25 numbers between brackets, pst-marble offers a utility for generating evenly spaced tines:

- [n S Ω tines]

- The tines command and its arguments are replaced by a sequence of n numbers. The difference between adjacent numbers is S and the center number is Ω when n is odd and S/2−Ω when n is even.

[2 600 -150 tines] is equivalent to

[-150 450]. For the 25 tine rake, uncomment

the rake line in actions= so that it looks like this;

then Compile:

0 0 48 colors 25 concentric-rings

90 [-150 450] 100 750 31 rake

-90 [-150 450] 100 750 31 rake

180 [ 25 50 0 tines ] 30 200 31 rake

% 0 230 shift

The top quarter of the marbling is less densely threaded than the

rest of the marbling. This is because, by raking downward without a

compensating upward raking, the whole design has been moved

downward. To recenter it pst-marble offers:

- θ R shift

- Shifts tank by R at θ degrees clockwise from vertical.

shift line will center the nonpareil

design; the value 230 was arrived at by trial and error:

0 0 48 colors 25 concentric-rings

90 [-150 450] 100 750 31 rake

-90 [-150 450] 100 750 31 rake

180 [ 25 50 0 tines ] 30 200 31 rake

0 230 shift

The nonpareil design is common in marbling, and is the basis for

more complicated designs as well. You can easily alter the

appearance by changing the actions= code.

The pst-marble reference card gives brief descriptions of all the

actions= commands. The next

installment in this tutorial series

explains how to rake curves.

Copyright © 2019 Aubrey Jaffer

| Topological Computer Graphics | ||

| Go Figure! | ||

Labels:

mathematical marbling,

nonpareil,

paint marbling,

pst-marble

Wednesday, January 16, 2019

Mathematical Marblilng Software

Jürgen Gilg and Luque Manuel have collaborated to create the pst-marble package on CTAN.org which lets you create your own mathematical marblings using LaTeX. https://ctan.org/pkg/pst-marble

http://pstricks.blogspot.com/2018/09/the-marbled-paper-with-pstricks.html

show nice examples of marblings you can create with pst-marble.

You can now create pst-marble designs online! The first tutorial (about the nonpareil pattern) is https://voluntocracy.blogspot.com/2019/02/mathematical-marbling-how-to.html

Labels:

CTAN,

LaTeX,

mathematical marbling,

paint marbling

Wednesday, October 10, 2018

The Lamb-Oseen Vortex and Paint Marbling

Just published The Lamb-Oseen Vortex and Paint Marbling on arXiv.

The image to the left shows the decay with time of the Lamb-Oseen vortex (starting from an impulse of circulation at the center point).

The image to the right shows the same vortex, but with exponentially increasing time. The rotational shear propagates to larger and larger orbits while the center returns to rest. While this animation returns to its original position, it could come to rest at any angle controlled by the magnitude of the initial circulation.

More about mathematical marbling.

Wednesday, August 15, 2018

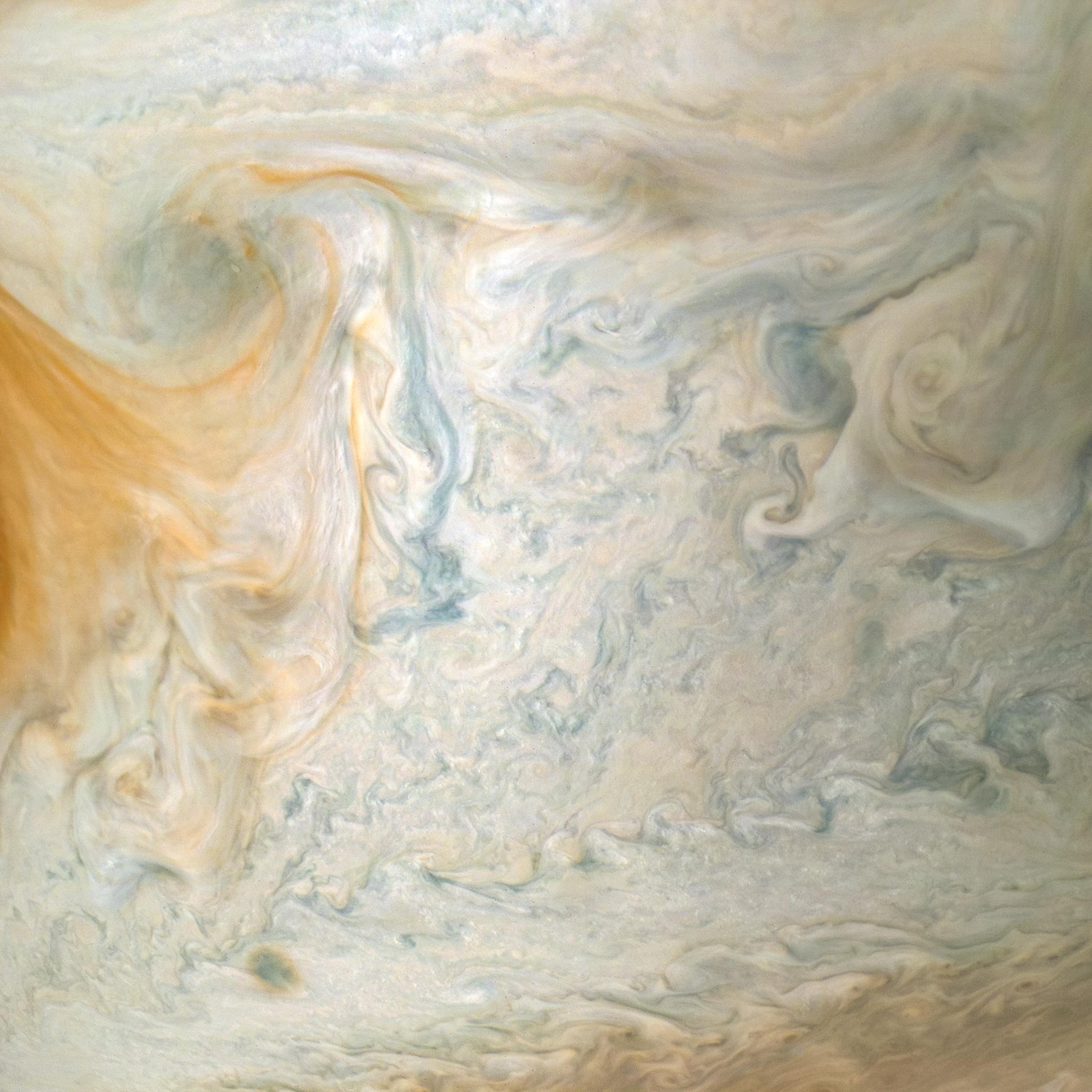

Vortex marbling in Jupiter's great spot

|

| Image from NASA's Juno spacecraft 2018-04-01 |

Friday, July 27, 2018

Bubbles in Marbling

| |

| Bubbles and parted paints |

While the formation of bubbles could be due to non-Newtonian fluid behavior, it is worth examining the conditions assuming a Newtonian fluid. A 25 mm diameter dowel submerged 12.5 mm will behave more like half of a 25 mm diameter sphere than a cylinder. If the kinematic viscosity (ν=0.001 m2/s) of the liquid is 1000 times that of water, then the Reynolds number is about 5, far less than the 90 needed to spawn vortexes. Re is inversely proportional to viscosity; reducing the kinematic viscosity by a factor of 10 raises Re to 50.

A half sphere of diameter d has buoyant-pressure (restoring force divided by cross-section area) of about 81 N/m2. Surface tension pressure (restoring force divided by cross-section area) of water is roughly 3.7 N/m2.

Drag is the force on the object moving through the tank fluid. There must be an equal and opposite net force on the liquid. Drag D for a sphere is the product of the friction coefficient CD, frontal area (π/4*d2), and dynamic head V2*ρ/2 (for water ρ=997). That force divided by the frontal area of the object is a pressure (suction actually).

A bubble will be formed if this suction behind the moving stylus is larger than the sum of the restoring forces at the liquid surface.

For ν=1000 mm2/s (1000 times that of water) the suction behind our 25 mm diameter dowel is 88 N/m2, which exceeds the restoring pressures 81 N/m2 and 3.7 N/m2, and bubbles can result.

The slower motions and smaller styluses that the St.Johns usually use have Reynolds numbers much smaller than 5. Thus the marblings they create don't evidence inertial effects (versus the mushroom designs of my previous post).

| |

| "Mushroom" flow from straight strokes |

In water, a 5 mm cylinder moving at 2 cm/s would shed vortexes 3 cm apart. A 1 mm diameter stylus moved in a straight path at 5 cm/s would not shed vortexes.

So existing evidence of Karman (shed) vortexes is only likely to be found in marbling produced on a tank filled with water.

Subscribe to:

Posts (Atom)